Vertical farm facades fail for the same reason most “green skyscraper” renders look great on Instagram but fall apart in real life: the envelope and MEP were never designed for actual plant physics.

Most vertical farm tower concepts ignore one brutal fact: plants are humidifiers with roots. Pack megawatts of LEDs and thousands of plants behind glass, and you get three hard problems very fast:

- Condensation and mold risk in the facade

- Unmanageable latent loads in the HVAC/DOAS system

- Lighting that either blows your PPFD targets or blinds every office across the street

This guide is a practical design brief for architects, MEP engineers, and operators who want a high-rise farm that can actually run: no streaming windows, no mystery moisture in the spandrels, and no grow rooms that feel like a sauna after the first crop cycle.

1. The Big Question: How do you stop a high-rise vertical farm facade from sweating itself to death?

Let’s strip it down to the real question:

How do you align indoor dew point, facade surface temperature, airflows, and lighting so that:

- You stay above the condensation line at the envelope

- Your DOAS and dehumidification can actually keep up with evapotranspiration

- You hit crop PPFD and DLI without turning the building into a light cannon or a greenhouse oven

Most concept towers, like the highly stylized Chicago vertical farm proposal covered by Yanko Design, focus on form and public narrative, not on how many kilograms of water per hour the lettuce is dumping into the air or what that does to the curtain wall on a -15 °C night. The result: beautiful renders, unbuildable physics.

To make a 2026-ready design that can pass peer review and code, you need to lock in five things early:

- Target indoor dew point and maximum allowable facade surface temperature drop

- Glazing U-value/SHGC and framing details that keep interior surfaces above that dew point, even at winter design conditions

- Dedicated outdoor air and desiccant/dehumidification sized for plant latent load, not office-people load

- Pressurization and air-change strategy that keeps moisture where you can manage it

- Lighting design (LED + daylight) that hits crop PPFD while managing glare and solar gain

2. What’s Really Going On: Dew point vs facade physics

2.1 Start with indoor dew point, not just “temperature and RH”

Growers talk in temperature and relative humidity. Facades care about dew point and surface temperature. In a high-density leafy greens room at 22–24 °C and 70–75% RH, you’re sitting around a 17–19 °C dew point. If your interior glazing surface drops below that, you are in active condensation territory.

Your design brief needs to state, in plain numbers:

- Design grow room condition: e.g. 24 °C, 70% RH (dew point ≈ 18 °C)

- Minimum interior facade surface temperature: must stay ≥ 20–21 °C at winter design

- Maximum RH drift: e.g. 5% band around setpoint during normal operation

That sets a clear target for U-value, thermal break performance, and air distribution at the glass. It also avoids the common mistake of back-calculating moisture control from an office HVAC spreadsheet that assumes people and computers, not thousands of transpiring plants.

2.2 Glazing, SHGC, and the "don’t sweat" envelope

Concept towers love single-skin glass boxes. Real grow towers need a different approach:

- U-value: Go as low as your budget and structure allow. Triple glazing or double glazing with high-performance low-e coatings will usually be required at cold-climate winter design conditions to keep interior surface temps above dew point.

- SHGC (Solar Heat Gain Coefficient): For LED-dominant grow rooms, treat uncontrolled solar like an enemy. Low to moderate SHGC reduces solar gain spikes and narrows HVAC sizing. In hotter climates, you’re likely aiming for SHGC ≤ 0.3 on most farm facades.

- Framing and thermal breaks: Thermally broken mullions and continuous insulation at slab edges are non-negotiable. Any metal that bridges indoor grow rooms to winter exterior is a condensation magnet.

Details matter. A facade can have great center-of-glass performance and still sweat at every framing member if the thermal breaks and gaskets are not designed for humid interior use. Treat every exposed metal edge as if it’s a chilled pipe: either insulate it, isolate it, or don’t run humid air across it.

2.3 Vapor control and air barriers: pick which side wins

In typical commercial towers, the inside is drier than the outside for most of the year. Vertical farms flip that. The interior is often wetter and at higher vapor pressure than outdoors, especially in shoulder and winter seasons.

That means:

- Your primary air/vapor barrier needs to be continuous and robust at the warm, humid side of the envelope.

- Penetrations for irrigation, fertigation, and LED cabling must be sealed like critical lab penetrations, not like standard office rough-ins.

- Mechanical rooms and shafts that connect farm and non-farm zones must be designed to avoid moist air migrating toward cold envelope surfaces.

Fail to control vapor, and water will find the first cold surface in your wall assembly, usually where nobody can see it until the insulation is ruined and the mold remediation contractor is taking pictures.

3. Practical Steps: MEP integration that actually controls moisture and light

3.1 Size dehumidification for plants, not people

Plants transpire hard. Depending on crop, density, and lighting, it is normal for 70–90% of irrigation water to come back into the air as moisture. In high-density lettuce or herbs, that can be several liters per square meter per day.

An effective design path looks like this:

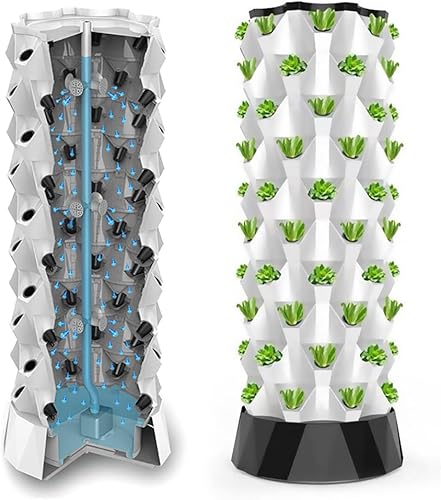

- Estimate evapotranspiration (ET) per crop zone. Use crop coefficient-based methods or empirical data from similar farms. If you’re running DWC, NFT, or high-density ebb-and-flow, don’t be conservative: overshoot ET in design, not in operation.

- Translate ET to latent load. 1 kg of water ≈ 2,400 kJ of latent heat. Every liter per hour of transpiration requires latent removal capacity.

- Size DOAS and desiccant/coil capacity for peak ET + ventilation. Your dedicated outdoor air system must handle outdoor humidity plus plant moisture without relying on “just open a louver and hope.”

Advanced farms are moving toward DOAS systems with desiccant wheels or liquid desiccant units to handle heavy latent loads efficiently, as similar humidity-control strategies are being explored in other high-moisture, process-driven industries. Those systems let you keep supply air dry enough to control RH while still running energy recovery effectively.

3.2 Air change, air paths, and pressurization

Once you know your moisture load, you define how air moves:

- Zone by crop type. Leafy greens, vine crops, and nursery areas all have different ideal RH and ET. Group similar crops, and give them separate air handlers where possible.

- Positive pressure in clean grow rooms. Keep farms slightly positive to adjacent corridors but balanced to the facade so you’re not pushing moist air into wall cavities.

- Use displacement or well-mixed air where it helps the facade. Deliver tempered, dehumidified air at low level and pull it up past crop zones and glass. This keeps boundary-layer air at the facade drier and slightly warmer.

Treat each grow floor more like a lab or cleanroom than a regular office floor. Document your pressure hierarchy and door states. If your door schedule and your pressure diagram don’t agree, moisture will pick the winner, and it won’t be you.

3.3 Condensate capture and reuse

The good news: all that latent load you’re removing is distilled water you can reuse. A few design rules:

- Collect by zone. Coil, DOAS, and dehumidifier condensate drain to dedicated, easy-to-flush piping. Avoid tying into sanitary where you can keep it clean.

- Treat and meter. UV or filtration plus basic monitoring before sending condensate back into fertigation or non-potable uses. Track volumes to validate your ET assumptions.

- Design storage with turnover. Don’t build a stagnant lake. Size tanks for realistic diurnal variation and regular turnover, then integrate into your fertigation plant.

This is also where good fluid-handling hardware matters. Vertical farms increasingly borrow from process industries, using higher-spec fittings, valves, and sanitary connections to keep condensate and nutrient circuits tight and easy to maintain, similar to the kinds of innovations described in industrial fluid-handling updates. Treat these systems as process utilities, not as afterthought plumbing.

3.4 Light without glare: PPFD mapping vs skyline impact

Lighting is where architecture, plant science, and urban comfort collide. On the plant side, you map PPFD and DLI by crop and stage. Flowering crops may run 600–900 µmol·m²·s in the canopy during bloom, as summarized in grower-facing PPFD guides. Leafy greens often run 200–350 µmol·m²·s with long photoperiods.

On the city side, uncontrolled bright windows create glare, light trespass, and unhappy neighbors.

Practical tactics:

- LED-forward design. Make LEDs the primary light source. Treat daylight as bonus PAR where it is controllable, not as the main grow engine.

- Internal baffles and reflectors. Use highly reflective interior surfaces and baffling so light is aimed at canopies, not straight out of the glass.

- Dynamic shading and facade frit. Integrate exterior or cavity shades and frit patterns where “public face” facades overlap with high-PPFD areas.

- Nighttime light policies. Limit overnight facade brightness. Many crops don’t need 24/7 light; align dark periods with the hours when light pollution is most sensitive.

LED layout should be co-designed with mechanical and architectural teams. If you’re stacking NFT or DWC tiers, your PPFD heat map should sit in the same BIM model as your ductwork, supply diffusers, and mullions. That’s how you avoid the classic “perfect lab render” that blasts 800 µmol straight into the skyline while leaving the back corners of the rack underlit.

4. Pro Tips & Benchmarks: What separates buildable vertical farms from pretty renders

4.1 Envelope & glazing benchmarks

- Target indoor dew point: 16–19 °C for most leafy/propagation rooms, depending on crop and disease pressure.

- Interior surface temperature: Keep ≥ 2–3 °C above design dew point at all envelope locations.

- Glazing: Double or triple low-e with U-values below typical office spec in cold climates; SHGC tuned to climate and facade orientation.

- Details: Explicit thermal break specification for all mullions and slab edge conditions. No exposed metal “fins” crossing from grow room to outdoors without separation.

4.2 Dehumidification & air system benchmarks

- Latent vs sensible: Expect latent loads that dominate sensible in mature crop rooms. Design coils and desiccants accordingly.

- Redundancy: N+1 on critical dehumidification and fans. A single failed dehumidifier should not push RH into disease territory overnight.

- Air changes: Tailor ACH to crop and tier density, but verify that air velocities at the facade are enough to prevent local stratification and cold, wet corners.

- Monitoring: Distributed temperature/RH and surface temperature sensors along the facade, feeding back into BAS alarms.

4.3 Lighting & controls benchmarks

- PPFD targets by crop: Leafy greens ~200–350 µmol·m²·s; fruiting/flowering crops often higher, per crop science and grower guides.

- Uniformity: Aim for at least 0.7–0.8 uniformity across each tier. Avoid hot spots near glass that push local leaf temperatures and transpiration far above average.

- Controls: Dimmable LEDs tied to PAR sensors and schedules. Ability to cut facade-adjacent rows first if you need to manage glare or thermal spikes.

- Integration: Lighting schedules coordinated with DOAS operation and setpoints to avoid humidity spikes when lights ramp up.

4.4 Commissioning and operations

Even the best design fails without commissioning tuned to plant biology:

- Envelope commissioning: Test vapor barrier integrity and air leakage under real pressure conditions before bringing plants in.

- HVAC/DOAS commissioning: Run acceptance tests with humidification to simulate plant loads. Verify dehumidification capacity, control stability, and facade surface temperatures at load.

- Lighting commissioning: Measure PPFD across all tiers and map against modeled values; adjust tilt, spacing, and dimming to close the gap.

- Operational playbooks: SOPs for “high humidity events” (pump failures, irrigation misfires, unexpected ET spikes) that include temporary setpoint shifts, pressure adjustments, and short-term lighting changes.

The real test of a vertical farm tower is not how it looks on opening day, but how stable the environment stays on the worst design day of the year, three crops into rotation, when the facade is cold, the plants are mature, and the maintenance team is busy elsewhere.

Get the dew point targets, glazing, air paths, and PPFD maps right at design stage, and your “living facade” becomes a controllable piece of infrastructure, not a permanent condensation experiment.

As an Amazon Associate, I earn from qualifying purchases.